What is Exothermic Weld ?

Exothermic Welding is used to Joint Copper to Copper or Copper to Steel where conductivity plays a very important role.

info@exothermicweld.com | tel. +91.22.28933996

![]() +919594899995

+919594899995

Exothermic Welding is used to Joint Copper to Copper or Copper to Steel where conductivity plays a very important role.

Exothermic Weld is a simple, cost-effective and permanent welded connection that uses a high-temperature exothermic reaction to create a molecular bond. It does not require an external heat or power source. Exothermic Weld is the universally preferred method for making permanent copper-to-copper and copper-to-steel electrical connections. Its performance is superior to all existing surface-to-surface mechanical connectors. Exothermic Weld works when others won’t!

There are many advantages of using Exothermic Weld. The most important one being that the process produces a molecular joint and not just a mechanical one in between the conductors. It is produced through a starting reactant which provides enough energy to activate the welding reaction. This takes place quickly and safely inside a graphite mould. The mould is designed specifically for a certain union depending on the elements to be welded and the joint type required. We guarantees all types of joints, not only copper cable unions but also to weld tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

In other words Exothermic Weld is a joining technique used to create a permanent connection between two metallic components. It involves a chemical reaction that generates heat, known as an exothermic reaction. This process is particularly noted for the durability of the bond produced and for preserving good electrical conductivity between the joined components. Creating a bond by exothermic weld typically involves heat created by a chemical reaction between some type of heavy metal oxide and a reducing agent. For example, iron oxide is a commonly used metal oxide and aluminum is a common reducing agent. These reactants produce heat extremely rapidly when ignited, thereby achieving the high temperatures needed for welding. Such heating is generally initiated once the parts to be joined are fitted together in a mold which contains the materials and the reaction as it takes place. Filler metal in liquid form is produced by this reaction and mixes with melted metal from the parts being joined to form a bond shaped by the mold. Molds used in exothermic weld may be made of graphite, ceramic, or other appropriate materials.

Exothermic Weld connects cables, ground rods, terminals and structures; the resulting molecular bond produces a permanent connection that won't loosen or corrode over the lifetime of the installation. You should use exothermically welded Connections when: you require long life/permanent connections; you expect high current faults; or corrosive conditions exist. The equipment required to make exothermic connections is lightweight, portable and does not require outside power. The resulting bond is a permanent joining of metallic parts that form an electrically conductive path. This will ensure electrical continuity and the capacity to conduct any potential current safely.

These permanent connections will carry as much, or more, current as the conductor. These connections eliminate bimetallic corrosion at the point of the weld. All strands of the conductor will equally share the current load.

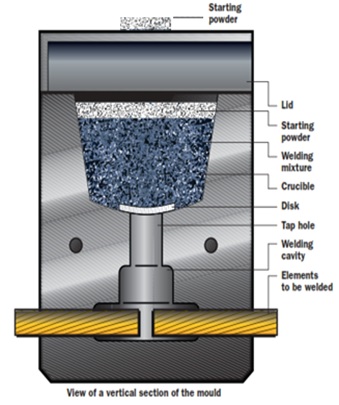

The Exothermic Weld System is a welding process that utilizes an exothermic reaction (a chemical reaction that releases energy in the form of very high temperatures and light) to permanently joins metal connections. Exothermic Weld uses a light-weight, clamp-on graphite mold to safely position and contains any weld required. The exothermic reaction creates an intense miniature furnace with temperatures exceeding 2,500 °F, instantly producing molten metal which flows into the weld cavity, filling any available space. After waiting adequate time after the initial process, the mold can be released and the finished connection removed.

When there is an improper connections between conductors which are often the reason for electrical malfunctions. A proper connection should have the following characteristics:

Only exothermic weld connections meet or exceed all of the above criteria. Exothermic Weld is recommended by IEEE and IEC. It has been shown to be the best choice where safety, reliability, longevity and current carrying capacity are critical. Exothermic Weld specifically supersedes its competition with its hermetically sealed metallized pouch which provides the product with an extensive shelf life and easy portability. Exothermic Weld is CPRI Tested and is the preferred method for making copper-to-copper and copper-to-steel electrical connections.

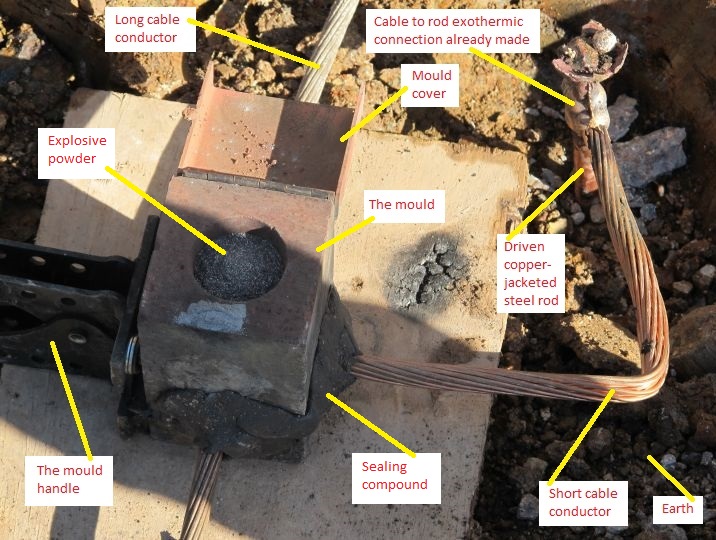

Exothermic Weld requires no outside source of power or heat - the system is also light and portable ideal for field use. Making an exothermic weld joint is a simple procedure which requires a mould, weld powder, handle clamp and exothermic weld tools. Exothermic Weld connections are tolerant to repeated fault currents, highly conductive, permanent and demonstrate excellent corrosion resistance - most exothermic weld connections have at least twice the cross-sectional area of the conductors being jointed.

Exothermic Weld is a very efficient and cost efficient method of making large or small numbers of high quality electrical connections. Exothermic Weld is a simple self-contained system that uses the high temperature reaction of powdered copper oxide and aluminium, within a mould, to form permanent electrical connections. The Exothermic Weld system requires no external power or heat source, creates high quality electrical connections, is completely portable, can be used safely with minimum training, is cost-effective and can be used for over 45 standard connection configurations. Exothermic Weld Connections have several advantages in that they are tolerant to repeated faults, are highly conductive, do not loosen and have excellent corrosion resistance because of the very high copper content (>90%) of the alloy.

An Exothermic Weld connection produces a joints superior in performance to any known mechanical or pressure type surface-to-surface contact connector. By virtue of its molecular bond, an Exothermic Weld Connection will not loosen or increase in resistance over the lifetime of the installation. Connections are often the weak point in ground circuits, especially if they are subjected to high currents and corrosion. The capacity of a grounding circuit to protect property and personnel depends on the quality of its connections. Only an exothermic weld connection can provide the permanent, low-resistance connection needed to create a long-lasting, reliable grounding network.

Exothermic Weld is often used to join copper conductors. The welding process joins two electrical conductors by use of superheated copper alloy. An exothermic reaction requires no external heat or current source. The reaction occurs between a copper thermite compositions that heat the copper. The chemical reaction is aluminothermic, occurring between aluminum powder and copper oxides. The reaction reaches very high temperatures. Reactant powders and a spark is all that is needed for a high energy reaction.Earth electrode and protective conductors are joined by exothermic weld process that employs superheated copper alloy to make permanent & maintenance free joint, avoiding unreliable screwed joints. Graphite Mould kits for all types of Grounding connections are available.

When Exothermic Weld is Used ?

Exothermic Weld is most commonly used for permanently joining copper conductors. It is the only acceptable means of bonding copper to galvanized cable. It can also be used on stainless steel, cast iron, steel, brass, bronze, and more. If joining two dissimilar metals, exothermic weld is a good option. You'll find Exothermic Weld.

The process of Exothermic Welding is a method of making electrical connections of copper to copper or copper to steel in which no outside source of heat or power is required. In this process, a special Welding material is placed into a high temperature resistant mold and ignited.

The process of igniting the particles creates extremely high heat and molten metal (exothermic reaction) up to 2000 degree celcious, and produces a molten metal slag. This liquid copper metal flows into the Welding cavity, filling any available space and completes the Welding. The Welding is then allowed to cool and solidify before it is removed from the mold. The mold is ready for the next Welding after a brief cleaning with a brush. This entire process takes only seconds to complete.

Exothermic Welding connections produce a permanent connection, superior in performance to any known mechanical or pressure type surface-to-surface contact connector. Because the connection produced is a molecular bond, an exothermic Weldinged connection will not loosen or increase in resistance over the lifetime of the installation.

The Exothermic Welding System is a welding process that utilizes an exothermic reaction to permanently join metal connections. Exothermic Welding uses a light-weight, clamp-on graphite mold to safely position and contains any weld required. The exothermic reaction creates an intense miniature furnace with temperatures exceeding 2,500 °F, instantly producing molten metal which flows into the weld cavity, filling any available space. After waiting adequate time after the initial process, the mold can be released and the finished connection removed.

Exothermic Weld system from AmiableWeld provides precision engineered molds for optimal results which gives about 30 to 100 Joints from one Graphite Mold. Features include simplicity, corrosion resistance, extended shelf life, high conductivity, portability, ease of use, and it requires no external heat or power source. Why Use Exothermic Weld : The Exothermic Weld Connecting created a permanent, homogeneous, and molecular bond that cannot loosen or corrode, and will carry more current that the conductor. The Exothermic Weld Connection are solid molecular bonds, they do not loosen or corrode over the lifetime of connection. The same cannot be said about other methods; such as brazing, crimp, split bolt, or compreion type connections.

Compared for some other forms of welding, exothermic bonds employ a greater mechanical toughness. The weld can be proof against corrosion. You simply won't notice an increase in electrical excess weight despite repeated small signal pulses; your weld is highly firm. The procedure is more costly, however. The task requires replaceable moulds, is not easily repeatable. Exothermic Weld may also be done far from others. That reduces dangers to employees. A igniter is used with widespread graphite molds or a palatable made drop within weld metal ink cartridge, semi-permanent graphite crucible pattern, and an ignition company that connects your container with a cord. Exothermic Weld is usually used for welding copper conductors but is suitable for welding a wide range of metals, including stainless steel, cast iron, common steel, brass, bronze, and Monel. It is especially useful for joining dissimilar metals. An Exothermic weld has higher mechanical strength than other forms of weld, and excellent corrosion resistance It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to other welding processes, requires a supply of replaceable moulds, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather.

Please visit our Website www.amiableimpex.com to explore our other products range that we Manufactures or Deals into.

Please visit our Other Website www.tinnedcopperbraid.com for Copper Braids and Copper Laminated Connectors as we are also the manufacturer for Copper Braids and Copper Flexible Connectors

Please also visit www.splitboltconnector.com as we also manufactures Split Bolt Connectors / Line Taps in India:

We sell to almost more than 30 countries in the world including India.

Amiable Impex sells in India at Ahmedabad, Pune, Delhi, Mumbai, Bangalore, Chennai, Kolkata, Surat, Pune, Lucknow, Kanpur, Nagpur, Indore, Bhopal, Vadodara(Baroda).

We also serves at: Andhra Pradesh - Hyderabad , Arunachal Pradesh - Itanagar, Assam - Dispur, Bihar - Patna , Chattisgadh - Raipur , Goa - Panaji ,Gujarat - Ahemdabad , Haryana - Chandigarh , Himachal Pradesh - Shimla , Srinagar, Jarkhand - Ranchi , Karnataka, Kerala - Thiruvanthapuram , Madhya Pradesh - Bhopal , Maharashtra - Mumbai , Manipur - Imphal , Meghalaya - Shillong , Mizoram - Aizwal , Nagaland - Kohima , Orissa - Bhubhaneshwar , Punjab - Chandigarh , Rajasthan - Jaipur , Sikkim - Gantok , Tamil Nadu - Chennai , Uttar Pradesh - Lucknow , Uttaranchal - Dehradun , West Bengal - Kolkata. Amiable Impex Sales are Worldwide. We export to Countries like Afganistan - Kabul, Albania - Tirane, Algeria - Algiers, Andorra - Andorra la Vella, Angola - Luanda, Antigua and Barbuda - Saint John's, Argentina - Buenos Aires, Armenia - Yerevan, Australia - Canberra, Austria - Vienna, Azerbaijan - Baku, The Bahamas - Nassau, Bahrain - Manama, Bangladesh - Dhaka, Barbados - Bridgetown, Belarus - Minsk, Belgium - Brussels, Belize - Belmopan, Benin - Porto-Novo, Bhutan - Thimphu, Bolivia - La Paz, Sucre, Bosnia and Herzegovina - Sarajevo, Botswana - Gaborone, Brazil - Brasilia, Brunei - Bandar Seri Begawan, Bulgaria - Sofia, Burkina Faso - Ouagadougou, Burundi - Bujumbura, Cambodia - Phnom Penh, Cameroon - Yaounde, Canada - Ottawa, Cape Verde - Praia, Central African Republic - Bangui Chad - N'Djamena, Chile - Santiago, China - Beijing, Colombia - Bogota, Comoros - Moroni, Congo Republic of the - Brazzaville, Congo, Democratic Republic of the - Kinshasa, Costa Rica - San Jose, Cote d'Ivoire - Yamoussoukro, Abidjan (de facto), Croatia - Zagreb, Cuba - Havana, Cyprus - Nicosia, Czech Republic – Prague, Denmark - Copenhagen, Djibouti - Djibouti, Dominica - Roseau, Dominican Republic - Santo Domingo, East Timor (Timor-Leste) - Dili, Ecuador - Quito, Egypt - Cairo, El Salvador - San Salvador, Equatorial Guinea – Malabo, Eritrea - Asmara, Estonia - Tallinn, Ethiopia - Addis Ababa, Fiji - Suva, Finland - Helsinki, France - Paris, Gabon - Libreville, The Gambia - Banjul, Georgia - Tbilisi, Germany - Berlin, Ghana - Accra, Greece - Athens, Grenada - Saint George's, Guatemala - Guatemala City, Guinea - Conakry, Guinea-Bissau - Bissau, Guyana - Georgetown, Haiti - Port-au-Prince, Honduras - Tegucigalpa, Hungary - Budapest, Iceland - Reykjavik,India - Delhi, Indonesia - Jakarta, Iran - Tehran, Iraq - Baghdad, Ireland - Dublin, Israel - Jerusalem, Italy - Rome, Jamaica - Kingston, Japan - Tokyo, Jordan - Amman, Kazakhstan - Astana, Kenya - Nairobi, Kiribati - Tarawa Atoll, Korea, North - Pyongyang, Korea, South - Seoul, Kosovo - Pristina, Kuwait - Kuwait City, Kyrgyzstan - Bishkek, Laos - Vientiane, Latvia - Riga, Lebanon - Beirut, Lesotho - Maseru, Liberia - Monrovia, Libya - Tripoli, Liechtenstein - Vaduz, Lithuania - Vilnius, Luxembourg - Luxembourg, Macedonia - Skopje, Madagascar - Antananarivo, Malawi - Lilongwe, Malaysia - Kuala Lumpur, Maldives - Male, Mali - Bamako, Malta - Valletta, Marshall Islands - Majuro, Mauritania - Nouakchott, Mauritius - Port Louis, Mexico - Mexico City, Micronesia, Federated States of - Palikir, Moldova - Chisinau, Monaco - Monaco, Mongolia - Ulaanbaatar, Montenegro - Podgorica, Morocco - Rabat, Mozambique - Maputo, Myanmar (Burma) - Rangoon (Yangon); Naypyidaw or Nay Pyi Taw, Namibia - Windhoek, Nauru, Nepal - Kathmandu, Netherlands - Amsterdam; The Hague, New Zealand - Wellington, Nicaragua - Managua, Niger - Niamey, Nigeria - Abuja, Norway - Oslo, Oman - Muscat, Pakistan - Islamabad, Palau - Melekeok, Panama - Panama City, Papua New Guinea - Port Moresby, Paraguay - Asuncion, Peru - Lima, Philippines - Manila, Poland - Warsaw, Portugal - Lisbon, Qatar - Doha, Romania - Bucharest, Russia - Moscow, Rwanda - Kigali, Saint Kitts and Nevis - Basseterre, Saint Lucia – Castries, Saint Vincent and the Grenadines - Kingstown, Samoa - Apia, San Marino - San Marino, Sao Tome and Principe - Sao Tome, Saudi Arabia - Riyadh, Senegal - Dakar, Serbia - Belgrade, Seychelles - Victoria, Sierra Leone - Freetown, Singapore - Singapore, Slovakia - Bratislava, Slovenia - Ljubljana, Solomon Islands - Honiara, Somalia - Mogadishu, South Africa - Pretoria, Cape Town, Bloemfontein, South Sudan - Juba, Spain - Madrid, Sri Lanka - Colombo; Sri Jayewardenepura Kotte, Sudan - Khartoum, Suriname - Paramaribo, Swaziland - Mbabane, Sweden - Stockholm, Switzerland - Bern, Syria - Damascus, Taiwan - Taipei, Tajikistan - Dushanbe, Tanzania - Dar es Salaam; Dodoma, Thailand - Bangkok, Togo - Lome, Tonga - Nuku'alofa, Trinidad and Tobago - Port-of-Spain, Tunisia - Tunis, Turkey - Ankara, Turkmenistan - Ashgabat, Tuvalu - Vaiaku village, Funafuti province, Uganda - Kampala, Ukraine - Kyiv, United Arab Emirates - Abu Dhabi, United Kingdom - London, United States of America - Washington D.C., Uruguay - Montevideo, Uzbekistan - Tashkent, Vanuatu - Port-Vila, Vatican City Holy See) - Vatican City, Venezuela - Caracas, Vietnam - Hanoi, Yemen - Sanaa, Zambia - Lusaka, Zimbabwe - Harare.