info@exothermicweld.com | tel. +91.22.28933996

![]() +919594899995

+919594899995

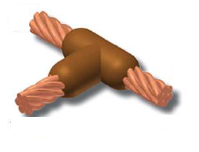

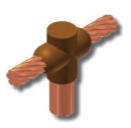

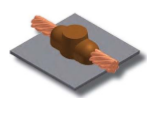

Exothermic Welding is most commonly used for permanently joining copper conductors or Copper Tapes / Copper Strips. It is the only acceptable means of bonding copper to Copper cable. Lightning protection and grounding systems require connections that maintain current carrying capacity exceeding that of the conductors used in the system. AMIABLE connections provide higher fusing capacity than the conductors to which they are bonded. It can also be used to Joint not only Copper but also Stainless steel, Cast iron, steel, Brass, Bronze, and other similar metals. For joining two dissimilar metals, exothermic welding is a good option. AMIABLEWELD meets these challenges and delivers assurance.

We Manufacture Exothermic Welding Powder and Exothermic Welds Graphite Mold and Supply and Provide Exothermic Welding Services also in Nepal- Kathmandu, Pokhara, Lalitpur, Biratnagar, Bharatpur, Birganj, Butwal, Dharan, Bhim Datta, Janakpur.

To view our Certificate please click here : E-Certificates Of Exothermic Welding

We as AmiableWeld are one of the biggest and largest Manufacturer of Exothermic Weld Powder and Exothermic Welding Graphite Mold in India and supply in overseas market. Our Exothermic Welding have passed all stringent test successfully as per IEEE 837 -2002 Earthing Substation Welding Standard. Our Products are ISO Certified and we are also awarded ISO 9001:2008, ISO 14001, ISO 18001 and our products are also CE and ROHS Compliance. We follow GMP as per International Standard.

For more details in regards to Accessories please click here

The Exothermic Welding Process is a simple, efficient method or welding Copper to Copper of Copper to Steel. One advantage is that No outside power is required when using the Exothermic Process. The exothermic process uses high temperature reaction of powdered copper oxide and aluminium. The reaction takes place in a semi-permanent graphite mold. These molds should last approximately forty or more welds if proper care is given. The reaction takes place very rapidly; therefore the total amount of heat applied to the conductors or surfaces is considerably less than that of brazing or soldering. This is important to remember when welding to insulated cable thin wall pipe.

This system is very field friendly, since its is light and portable and requires no outside power source. It requires very little time or skill to obtain an efficient, maintenance free connection when using this Exothermic Welding Process.

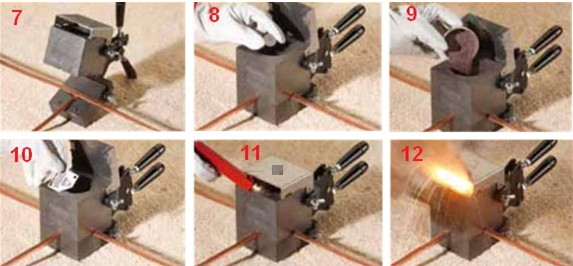

STEP - 1:

Always wear protective safety glasses and gloves while working with exothermic welding products.

STEP - 2:

Gather all the proper material and equipment/accessories for the type of connection you are making. The typical Weld system requires all the Accessories as listed on Exothermic Weld Accessories page. Check to ensure the graphite Mould is not worn or broken, which could cause leakage of molten weld metal.

STEP - 3:

Slide the handle clamp into the pre-drilled holes with the proper orientation for the thumbscrews.

STEP - 4:

Tighten the clamp thumbscrews onto the mould.

STEP - 5:

Close the grips too tighly lock the Mould. Make adjustments to tighten/loosen the handle clamp.

STEP - 6:

The material to be welded (cable, rod, tape etc.) must be clean using the wire Brush and dry using the Flame Torch included in the set of accessories. Thus the oxide layer and superficial impurity is eliminated. Given that the graphite mould also absorbs moisture, this should be removed by preheating with a gas welding torch again to avoid a porous welding.

P.N - After the first welding is done, it is not necessary to re-heat the mould if the next welding is done within 15 minutes as it conserves the previously generated heat.

STEP - 7:

Place the conductors in the mould and close the handle clamps to avoid material leakages during the reaction.

P.N – Always apply Sealing Compound at the places where the conductors is passing from the mould else at the time of Welding, the Exothermic Liquid will spread out as a flame resulting in improper joint

STEP - 8:

Place the metallic disk inside the mould and ensure that Powder should not enter into Weld Cavity.

STEP - 9:

Pour Exothermic Weld Powder into Graphite Mould. (Pour the Powder recommended and supplied by us)

STEP - 10:

Empty 50% of the starting powder above Exothermic Weld Powder(Don’t Mix, just scatter)and then Close the Mould Mouth and then the rest 50% Starting Powder, sprinkle it on the Mould Mouth nearby the small hole given on the top of the Mould Mouth.

STEP - 11:

Ignite the starting powder extended on the top/side of the mould using the flint igniters.

STEP - 12:

Once started, the reaction will take 8-20 seconds during which it is recommended to stand clear of the mold.

STEP - 13:

After at least 3 minutes of the Mould cooling down, open the moldby undoing the handle grip. Remove the mold from the joint andclean the joint by removing slag with help of Slag Removal Tooland hard brush. Then clean the weld cavity with soft brush gently.The mould will be ready now to use again without having to reheatit as it is already warm.

Please Click here to see more for the process of Exothermic Welding.

Exothermic Welded connections provides a permanent connection that is superior in performance to any other known mechanical or pressure type surface-to-surface contact connector. Because the connection produced is a molecular bond, an exothermic welding connection will not loosen or corrode.

Exothermic Welding is require when there is an improper connections between two conductors which are often the reason for electrical malfunctions. A proper connection should have the following characteristics:

Only exothermic weld connections meet or exceed all of the above criteria. Exothermic weld is recommended by IEEE and IEC (International Standard Body).

Listed below are the main features of these products:

| Cable To Cable Joints | Cable to Rod Joints |

|---|---|

|

|

| Cable To Bar,Joints | Cable To Surface,(Steel/Copper) Joints |

|

|

| Bar to Bar Connections (BB) | Bar To Ground Rod,Connections (BR) |

|

|

AMIABLEWELD are the leading Supplier of Exothermic Weld Powder in India supplying to Power Industries, Transformers Industries, Raliways, Hydro Companies, Defence Company etc. Please click here to find more Joint which is being made from our Exothermic Weld:

P.N - If you do not see the connection, configuration or size of the conductor required by you mentioned in this product catalog then please contact us at info@exothermicweld.com

| OUR SUMMARY | |

| REVIEWER | AMIABLE IMPEX |

| REVIEW DATE | 17-12-2016 |

| REVIEWED ITEM | EXOTHERMIC WELDING MANUFACTURER & SUPPLIER IN Nepal |

| AUTHOR RATING |

|

Please visit our Other Websites for Exothermic Weld Materials:

Please visit our Website

Please visit our Other Website

Please also visit

We sell to almost more than 30 countries in the world including India.

Amiable Impex sells in India at Ahmedabad, Pune, Delhi, Mumbai, Bangalore, Chennai, Kolkata, Surat, Pune, Lucknow, Kanpur, Nagpur, Indore, Bhopal, Vadodara(Baroda).

We also serves at: Andhra Pradesh - Hyderabad , Arunachal Pradesh - Itanagar, Assam - Dispur, Bihar - Patna , Chattisgadh - Raipur , Goa - Panaji ,Gujarat - Ahemdabad , Haryana - Chandigarh , Himachal Pradesh - Shimla , Srinagar, Jarkhand - Ranchi , Karnataka, Kerala - Thiruvanthapuram , Madhya Pradesh - Bhopal , Maharashtra - Mumbai , Manipur - Imphal , Meghalaya - Shillong , Mizoram - Aizwal , Nagaland - Kohima , Orissa - Bhubhaneshwar , Punjab - Chandigarh , Rajasthan - Jaipur , Sikkim - Gantok , Tamil Nadu - Chennai , Uttar Pradesh - Lucknow , Uttaranchal - Dehradun , West Bengal - Kolkata.

Amiable Impex Sales are Worldwide. We export to Countries like Afganistan - Kabul, Nepal - Tirane, Nepal - Algiers, Andorra - Andorra la Vella, Angola - Luanda, Antigua and Barbuda - Saint John's, Argentina - Buenos Aires, Armenia - Yerevan, Australia - Canberra, Austria - Vienna, Azerbaijan - Baku, The Bahamas - Nassau, Bahrain - Manama, Bangladesh - Dhaka, Barbados - Bridgetown, Belarus - Minsk, Belgium - Brussels, Belize - Belmopan, Benin - Porto-Novo, Bhutan - Thimphu, Bolivia - La Paz, Sucre, Bosnia and Herzegovina - Sarajevo, Botswana - Gaborone, Brazil - Brasilia, Brunei - Bandar Seri Begawan, Bulgaria - Sofia, Burkina Faso - Ouagadougou, Burundi - Bujumbura, Cambodia - Phnom Penh, Cameroon - Yaounde, Canada - Ottawa, Cape Verde - Praia, Central African Republic - Bangui Chad - N'Djamena, Chile - Santiago, China - Beijing, Colombia - Bogota, Comoros - Moroni, Congo Republic of the - Brazzaville, Congo, Democratic Republic of the - Kinshasa, Costa Rica - San Jose, Cote d'Ivoire - Yamoussoukro, Abidjan (de facto), Croatia - Zagreb, Cuba - Havana, Cyprus - Nicosia, Czech Republic – Prague, Denmark - Copenhagen, Djibouti - Djibouti, Dominica - Roseau, Dominican Republic - Santo Domingo, East Timor (Timor-Leste) - Dili, Ecuador - Quito, Egypt - Cairo, El Salvador - San Salvador, Equatorial Guinea – Malabo, Eritrea - Asmara, Estonia - Tallinn, Ethiopia - Addis Ababa, Fiji - Suva, Finland - Helsinki, France - Paris, Gabon - Libreville, The Gambia - Banjul, Georgia - Tbilisi, Germany - Berlin, Ghana - Accra, Greece - Athens, Grenada - Saint George's, Guatemala - Guatemala City, Guinea - Conakry, Guinea-Bissau - Bissau, Guyana - Georgetown, Haiti - Port-au-Prince, Honduras - Tegucigalpa, Hungary - Budapest, Iceland - Reykjavik,India - Delhi, Indonesia - Jakarta, Iran - Tehran, Iraq - Baghdad, Ireland - Dublin, Israel - Jerusalem, Italy - Rome, Jamaica - Kingston, Japan - Tokyo, Jordan - Amman, Kazakhstan - Astana, Kenya - Nairobi, Kiribati - Tarawa Atoll, Korea, North - Pyongyang, Korea, South - Seoul, Kosovo - Pristina, Kuwait - Kuwait City, Kyrgyzstan - Bishkek, Laos - Vientiane, Latvia - Riga, Lebanon - Beirut, Lesotho - Maseru, Liberia - Monrovia, Libya - Tripoli, Liechtenstein - Vaduz, Lithuania - Vilnius, Luxembourg - Luxembourg, Macedonia - Skopje, Madagascar - Antananarivo, Malawi - Lilongwe, Malaysia - Kuala Lumpur, Maldives - Male, Mali - Bamako, Malta - Valletta, Marshall Islands - Majuro, Mauritania - Nouakchott, Mauritius - Port Louis, Mexico - Mexico City, Micronesia, Federated States of - Palikir, Moldova - Chisinau, Monaco - Monaco, Mongolia - Ulaanbaatar, Montenegro - Podgorica, Morocco - Rabat, Mozambique - Maputo, Myanmar (Burma) - Rangoon (Yangon); Naypyidaw or Nay Pyi Taw, Namibia - Windhoek, Nauru, Nepal - Kathmandu, Netherlands - Amsterdam; The Hague, New Zealand - Wellington, Nicaragua - Managua, Niger - Niamey, Nigeria - Abuja, Norway - Oslo, Oman - Muscat, Pakistan - Islamabad, Palau - Melekeok, Panama - Panama City, Papua New Guinea - Port Moresby, Paraguay - Asuncion, Peru - Lima, Philippines - Manila, Poland - Warsaw, Portugal - Lisbon, Qatar - Doha, Romania - Bucharest, Russia - Moscow, Rwanda - Kigali, Saint Kitts and Nevis - Basseterre, Saint Lucia – Castries, Saint Vincent and the Grenadines - Kingstown, Samoa - Apia, San Marino - San Marino, Sao Tome and Principe - Sao Tome, Saudi Arabia - Riyadh, Senegal - Dakar, Serbia - Belgrade, Seychelles - Victoria, Sierra Leone - Freetown, Singapore - Singapore, Slovakia - Bratislava, Slovenia - Ljubljana, Solomon Islands - Honiara, Somalia - Mogadishu, South Africa - Pretoria, Cape Town, Bloemfontein, South Sudan - Juba, Spain - Madrid, Sri Lanka - Colombo; Sri Jayewardenepura Kotte, Sudan - Khartoum, Suriname - Paramaribo, Swaziland - Mbabane, Sweden - Stockholm, Switzerland - Bern, Syria - Damascus, Taiwan - Taipei, Tajikistan - Dushanbe, Tanzania - Dar es Salaam; Dodoma, Thailand - Bangkok, Togo - Lome, Tonga - Nuku'alofa, Trinidad and Tobago - Port-of-Spain, Tunisia - Tunis, Turkey - Ankara, Turkmenistan - Ashgabat, Tuvalu - Vaiaku village, Funafuti province, Uganda - Kampala, Ukraine - Kyiv, United Arab Emirates - Abu Dhabi, United Kingdom - London, United States of America - Washington D.C., Uruguay - Montevideo, Uzbekistan - Tashkent, Vanuatu - Port-Vila, Vatican City Holy See) - Vatican City, Venezuela - Caracas, Vietnam - Hanoi, Yemen - Sanaa, Zambia - Lusaka, Zimbabwe - Harare.

Make sure you use the free online HTML cleanup tool to avoid bad HTML practices on your website.

Exothermic Welding Manufacturer Supplier in Tirana - Nepal

Exothermic Welding Manufacturer Supplier in Durres - Nepal

Exothermic Welding Manufacturer Supplier in Elbasan - Nepal

Exothermic Welding Manufacturer Supplier in Vlore - Nepal

Exothermic Welding Manufacturer Supplier in Shkoder - Nepal

Exothermic Welding Manufacturer Supplier in Korce - Nepal

Exothermic Welding Manufacturer Supplier in Fier - Nepal

Exothermic Welding Manufacturer Supplier in Berat - Nepal

Exothermic Welding Manufacturer Supplier in Lushnje - Nepal

Exothermic Welding Manufacturer Supplier in Kavaje - Nepal